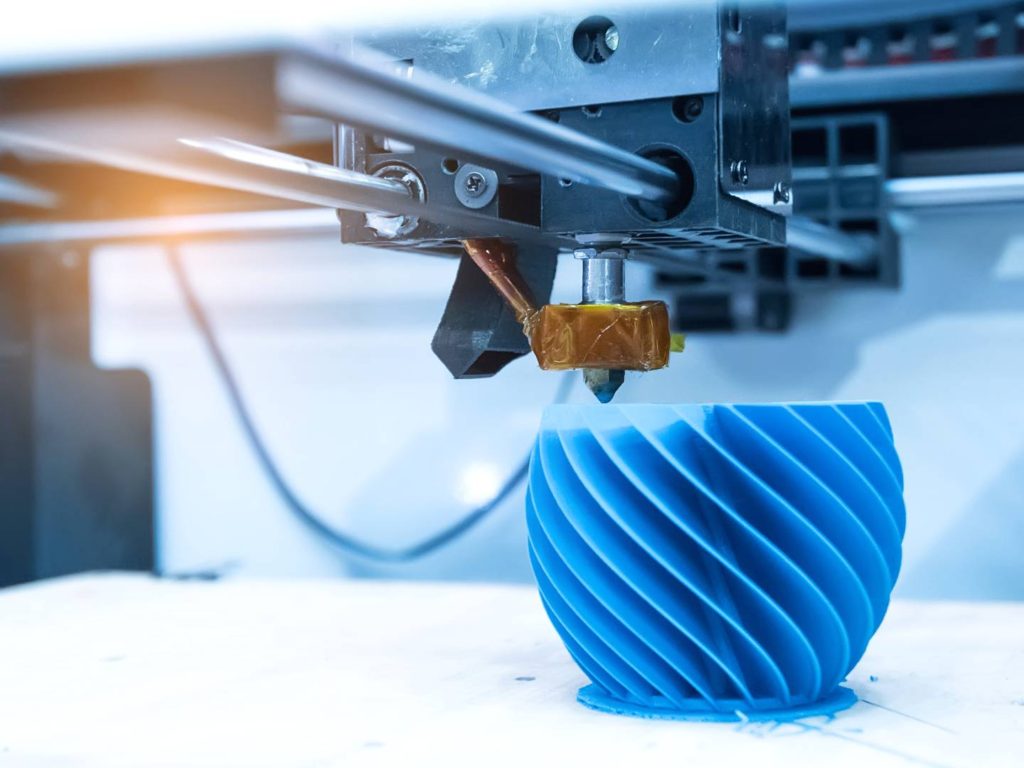

This fused deposition model, or fdm 3d Printing, is the additive building technique where layers of elements are fused collectively in a design to build an object. The element is generally melted only past its glassful transition temp and then expelled in the pattern close to or right on top of prior extrusions, making an object layer after layer.

A layman, a standard FDM 3D printer, uses a plastic fibre and presses it through the hot end, rendering it and then putting it in layers on a print bed. The layers are then fused, making up during the print, and apparently, they’ll form the completed part.

Many kinds of items can be utilized with the FDM methods, alongside the most popular thermoplastics, pastes, chocolate, and even some of the “exotic” items like metal- or the wood-instilled thermoplastic.

Variations in a Design and the Capability

Variations in an extrusion system of the fused ousting modelling 3D printer include, however, are not confined to:

- The filament extruders, amongst the most versatile and common variation that utilizes reel of the thermoplastic filament

- The Pellet extruder, exchanging a filament for the granules of a plastic

- The chocolate extruders

- The paste extruder, where a paste can easily be extruded. The known uses are food and ceramics. Paste extrusion at times is left in its very own category, as a paste isn’t necessarily the thermoplastic material.

Benefits

FDM provides a no. of benefits over other techniques of 3D Printing. Let’s take a look at the advantages that are as follows-

- One of FDM 3D print’s major benefits is scalability: This could be scaled via any size. It’s because the constraint in size of the build area is a movement of every gantry – making the gantry rail longer and a build area could be made magnanimous. There are some minor issues, and a particular point, the cost’s no longer balanced by the advantages. However, no other printer design is capable of being mounted as easily with some problems as FDM.

- One of the other obvious advantages of having a simply-scalable intention is a cost-to-the-size ratio. The FDM printer is continuously being made less expensive & bigger, due to a low part cost and a simple design. Other printer methods cost several times more every unit region of the build volume because they are challenging to mount up and the major components are yet quite expensive.

- Another benefit is material versatility. On any of the FDM printers, a wider range of thermoplastic material and exotic filament could be printed with some modifications and upgrades, something that can’t be said of several other styles where material should be the resin or a fine powder.

Well, that is very much all you have here to read and learn about FDM 3d printing. To know further, you may look over the web where you will go on to gather more and more info.